Engine Repair Training: How to Learn Essential Skills, Tools, and Safety Practices for Automotive Maintenance

Engine repair training provides a solid foundation for anyone interested in maintaining and repairing automotive engines. This article explains what to expect from a typical training program, including hands-on practice with essential tools, learning diagnostic techniques, and understanding important safety procedures. By exploring the key skills taught and the structure of different courses, you can make an informed decision about which training best fits your goals. Whether you are new to automotive maintenance or looking to expand your expertise, proper training is an important step toward working confidently and safely with engines.

What are the essential skills for engine repair?

Engine repair requires a diverse set of skills that combine technical knowledge with practical expertise. The fundamental skills include understanding engine components and their functions, diagnosing problems accurately, and performing repairs efficiently. Technicians must be proficient in using diagnostic tools, reading service manuals, and interpreting technical data. Additionally, they need to develop strong problem-solving abilities to troubleshoot complex issues and determine the best course of action for repairs.

Critical thinking and attention to detail are paramount in engine repair. Technicians must be able to analyze symptoms, consider multiple potential causes, and systematically eliminate possibilities to identify the root problem. Mastery of these skills enables mechanics to tackle a wide range of engine issues, from simple maintenance tasks to complex overhauls.

How can one choose the right engine repair training program?

Selecting the appropriate engine repair training program depends on several factors, including your current skill level, career goals, and available resources. Look for programs that offer a comprehensive curriculum covering both theoretical knowledge and hands-on experience. Accredited vocational schools, community colleges, and technical institutes often provide well-structured courses that meet industry standards.

When evaluating programs, consider the following aspects:

-

Curriculum content: Ensure the program covers essential topics such as engine theory, diagnostics, repair techniques, and safety protocols.

-

Practical training: Look for courses that offer substantial hands-on experience with real engines and modern diagnostic equipment.

-

Instructor qualifications: Research the expertise and industry experience of the teaching staff.

-

Facility and equipment: Check if the training center has up-to-date tools and equipment that reflect current industry standards.

-

Industry recognition: Verify if the program is recognized by automotive manufacturers or industry associations.

What career opportunities are available after engine repair training?

Completing engine repair training opens up a variety of career paths in the automotive industry. Graduates can pursue roles such as automotive service technicians, engine specialists, or diesel mechanics. Many find employment in dealerships, independent repair shops, or fleet maintenance facilities. Some technicians specialize in specific types of engines or vehicles, such as high-performance engines or heavy-duty trucks.

As you gain experience, you may have opportunities to advance to supervisory positions like shop foreman or service manager. Entrepreneurial-minded individuals might consider opening their own repair shops. Additionally, the skills acquired in engine repair training can be valuable in related fields such as automotive engineering, technical writing, or automotive education.

How important is safety training in engine repair courses?

Safety training is a critical component of any reputable engine repair program. Working with engines involves potential hazards such as exposure to chemicals, high temperatures, and moving parts. Comprehensive safety training covers topics like proper use of personal protective equipment (PPE), safe handling of tools and machinery, and understanding workplace hazards.

Students learn about fire safety, electrical safety, and proper ventilation practices. They also receive instruction on ergonomics to prevent repetitive strain injuries and proper lifting techniques to avoid back injuries. Understanding and implementing these safety practices not only protects technicians but also ensures compliance with workplace safety regulations and promotes a culture of safety in the automotive industry.

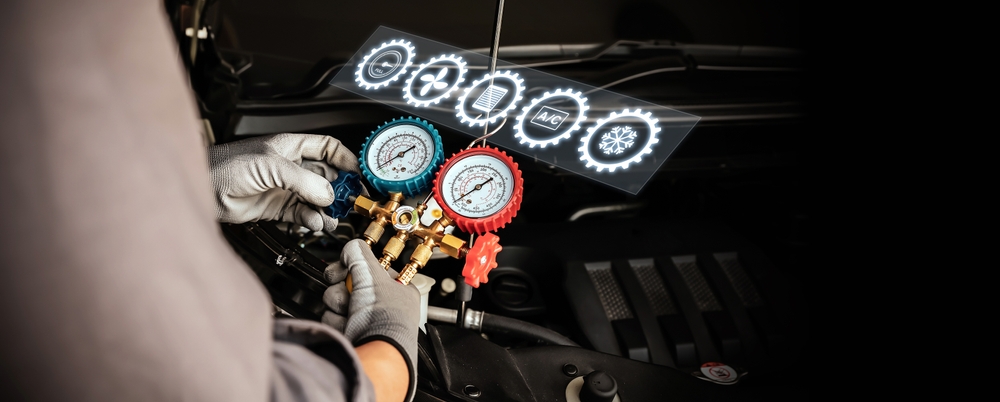

What tools and equipment are typically used in engine repair?

Engine repair training familiarizes students with a wide array of tools and equipment essential for diagnosing and repairing modern engines. Basic hand tools include wrenches, sockets, screwdrivers, and pliers. Specialized tools like torque wrenches, compression testers, and timing lights are used for specific engine maintenance tasks.

Advanced diagnostic equipment plays a crucial role in modern engine repair. Students learn to use onboard diagnostic (OBD) scanners, multimeters, and oscilloscopes to interpret engine data and pinpoint issues. Engine stands and hoists are employed for safely removing and working on engines. Training programs also introduce students to computerized engine management systems and the software used to interface with these systems.

How do training costs and program durations compare across different institutions?

Engine repair training programs vary in cost and duration depending on the institution and the level of certification offered. To give you an idea of what to expect, here’s a comparison of different training options:

| Institution Type | Program Duration | Estimated Cost | Key Features |

|---|---|---|---|

| Community College | 2 years (Associate’s Degree) | $5,000 - $15,000 | Comprehensive curriculum, potential for credits transfer |

| Vocational School | 6-12 months | $3,000 - $10,000 | Focused training, faster entry into workforce |

| Technical Institute | 9-18 months | $10,000 - $20,000 | Advanced equipment, industry partnerships |

| Manufacturer-Specific Program | 2-6 weeks | $1,000 - $5,000 | Brand-specific training, often required for dealership positions |

| Online Courses | Self-paced | $500 - $2,000 | Flexible schedule, limited hands-on experience |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

When choosing a program, consider not only the cost but also the value provided in terms of hands-on experience, industry connections, and job placement assistance. Some institutions offer financial aid or payment plans to help manage the cost of training. Additionally, apprenticeship programs may provide paid on-the-job training, allowing you to earn while you learn.

Engine repair training is an investment in your future career. By carefully evaluating your options and choosing a program that aligns with your goals and resources, you can acquire the skills and knowledge necessary to succeed in the automotive repair industry. Remember that continuous learning and staying updated with evolving engine technologies will be crucial for long-term success in this dynamic field.

The shared information of this article is up-to-date as of the publishing date. For more up-to-date information, please conduct your own research.